The pharmaceutical industry is one of the most heavily regulated sectors in the world. Stringent regulations govern every aspect of the supply chain—from manufacturing to final delivery—to ensure that medicines and medical devices are safe, effective, and secure. Navigating this complex regulatory landscape is challenging, especially when transporting sensitive, high-value, or controlled substances. This is where an Advanced Transportation Management System (TMS) becomes invaluable.

In this blog, we'll explore how an advanced TMS helps pharmaceutical companies meet regulatory requirements, maintain compliance, and improve operational efficiency.

Key Regulatory Challenges in the Pharmaceutical Supply Chain

1. Temperature-Controlled Transportation (Cold Chain Management)

Many pharmaceutical products, such as vaccines, biologics, and insulin, are highly sensitive to temperature fluctuations. Regulatory agencies like the FDA, EMA, and WHO enforce strict guidelines to ensure that temperature-controlled (cold chain) products are stored and transported within the specified temperature range. The failure to maintain the correct temperature can result in product spoilage, leading to loss of efficacy and potential harm to patients.

2. Serialization and Product Traceability (Track and Trace)

Regulations such as the Drug Supply Chain Security Act (DSCSA) in the U.S. and the Falsified Medicines Directive (FMD) in the European Union require full traceability of pharmaceutical products throughout the supply chain. Serialization codes on drug packages enable end-to-end tracking, ensuring that each product can be traced back to its origin and verified as authentic.

3. Good Distribution Practice (GDP) Compliance

GDP regulations focus on the proper handling, storage, and transportation of pharmaceutical products. They require companies to implement strict protocols to ensure the safety and quality of products during transportation, especially for temperature-sensitive items. Non-compliance can lead to product recalls, legal penalties, and reputational damage.

4. Regulated Substances and Security Protocols

Controlled substances like opioids and psychotropic drugs require additional regulatory oversight due to their potential for misuse. Companies must comply with security requirements, including background checks for personnel handling these substances, secure packaging, real-time monitoring, and incident reporting.

5. Auditing, Documentation, and Reporting

Audits are a routine part of regulatory compliance in the pharmaceutical industry. Authorities may request proof of adherence to cold chain protocols, proper handling of controlled substances, or documentation on transportation routes. Inaccurate or incomplete records can lead to penalties, product recalls, or even loss of licenses.

How an Advanced TMS Helps Navigate Regulatory Challenges

An advanced TMS streamlines pharmaceutical logistics by automating critical processes, ensuring visibility, and facilitating real-time monitoring. Here’s how a robust TMS helps pharmaceutical companies maintain compliance with stringent regulations:

1. Cold Chain Monitoring and Control

An advanced TMS integrates with IoT sensors to continuously monitor the temperature of sensitive pharmaceutical shipments. Real-time temperature tracking ensures that products remain within the required temperature range throughout the journey. If any deviation occurs, the system triggers alerts and enables immediate corrective action, preventing potential damage to the products.

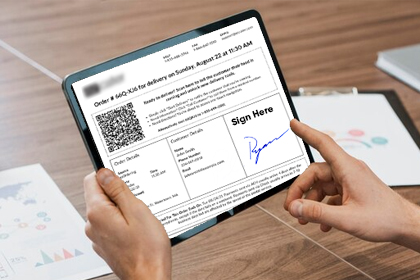

2. Serialization and Full Product Traceability

A TMS enables pharmaceutical companies to comply with track-and-trace regulations by offering end-to-end visibility across the supply chain. It ensures that every step of the transportation process—from loading to delivery—can be tracked and logged, providing a digital record that ensures compliance with serialization and traceability laws.

3. Automated Documentation for Audits

One of the most critical challenges in pharmaceutical logistics is managing and presenting documentation for audits. A TMS automates the generation and storage of all required documentation, such as temperature logs, chain-of-custody reports, and transportation routes. This digital documentation can be retrieved instantly for inspections, reducing the administrative burden and ensuring regulatory compliance.

4. Risk Management for Controlled Substances

For companies dealing with controlled substances, an advanced TMS ensures compliance with strict security regulations by providing secure route planning, real-time GPS tracking, and remote monitoring capabilities. Geofencing can be set up to send alerts if a vehicle carrying controlled substances strays from the designated route, ensuring tight security.

5. Route Optimization for Regulatory Efficiency

Advanced route optimization features in a TMS not only reduce delivery times and fuel costs but also help ensure compliance with regulations. The system can plan routes that meet GDP requirements, avoid high-risk areas, and comply with transportation laws specific to certain jurisdictions (e.g., avoiding temperature-sensitive zones in extreme weather conditions).

6. Regulatory Reporting and Compliance Alerts

An advanced TMS provides built-in reporting tools that generate custom compliance reports tailored to specific regulatory needs. These reports can be automatically sent to regulatory authorities, partners, or internal compliance teams. The system can also issue real-time compliance alerts if a shipment is at risk of violating regulatory standards, allowing companies to proactively address issues before they escalate.

Additional Benefits of an Advanced TMS for Pharmaceutical Companies

1. Increased Efficiency and Lower Costs

By automating compliance-related tasks, an advanced TMS reduces the amount of manual intervention required. This not only improves accuracy but also reduces administrative costs associated with managing regulatory compliance.

2. Improved Customer Satisfaction

With enhanced visibility and the ability to ensure timely delivery of pharmaceutical products in optimal condition, companies can build trust with customers. Consistent delivery of high-quality products contributes to a stronger brand reputation.

3. Proactive Risk Management

An advanced TMS helps companies identify potential risks, such as delayed shipments or route deviations, in real time. This allows for proactive measures to be taken, minimizing the chances of non-compliance or shipment delays.

4. Future-Proofing Against Regulatory Changes

The pharmaceutical industry is constantly evolving, and so are the regulations governing it. An advanced TMS can be updated to accommodate new regulatory requirements, ensuring companies stay ahead of compliance challenges.

Conclusion

Navigating the complexities of pharmaceutical regulations requires more than just diligence—it demands technological innovation. An advanced Transportation Management System (TMS) is a critical tool in ensuring compliance with global regulatory standards, particularly in managing temperature-sensitive products, tracking shipments, and maintaining secure transportation for controlled substances. By integrating a TMS into your pharmaceutical supply chain, your company can mitigate risks, streamline operations, and maintain a compliant and efficient supply chain that ensures patient safety.

Ensure your pharmaceutical logistics are fully compliant with global regulations by leveraging NaaviQ TMS. Book a demo today and discover how our advanced TMS can simplify your regulatory challenges while optimizing your logistics operations.